- HEALTHCARE

-

CAREERS

-

Careers

- CONTACT

Explore all Aerospace Products

Blisk blade

OGV blade

Fan blade

Shaft

LPC Disc

HP Disc

Aft

Flap Track

Trailing Arm

Upper Torque Link

Our facilities include:

Ready for aerospace

Virtual Manufacturing

Forging

Machining

Heat Treatment

Chemical Processing

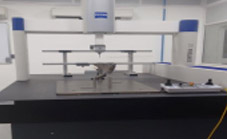

Testing

Our BFL Testing Capabilities include: